Something to look forward to: It looks like Intel is making steady progress on 10nm production and 7nm development. Component and substrate shortages may lead to fewer processors being made in the coming months, but CEO Pat Gelsinger is hopeful the inflection point is coming later this year. Meanwhile, Intel has beat financial Q2 2021 estimates as revenue grew 2% to $18.5 billion.

Intel is optimistic about its 2021 outlook. The company reported second quarter net income of $5.1 billion on revenue of $19.6 billion. This is higher than Wall Street’s expectations of $18.5 billion in earnings, and the company is now projecting a stronger non-GAAP revenue of $73.5 billion for 2021.

CEO Pat Gelsinger says the semiconductor industry has seen tremendous growth thanks to the accelerated “digitization of everything,” and that this trend will most likely persist for the next ten years as people and companies increasingly opt for hybrid work models.

The pandemic has driven demand for desktop and laptop PCs, and Intel believes its newest CPUs sporting Evo branding have a good chance of capturing a good chunk of the 400 million people who are expected to upgrade their systems in the coming years. On the other hand, the most recent data from IDC indicates demand is already slowing as restrictions are eased.

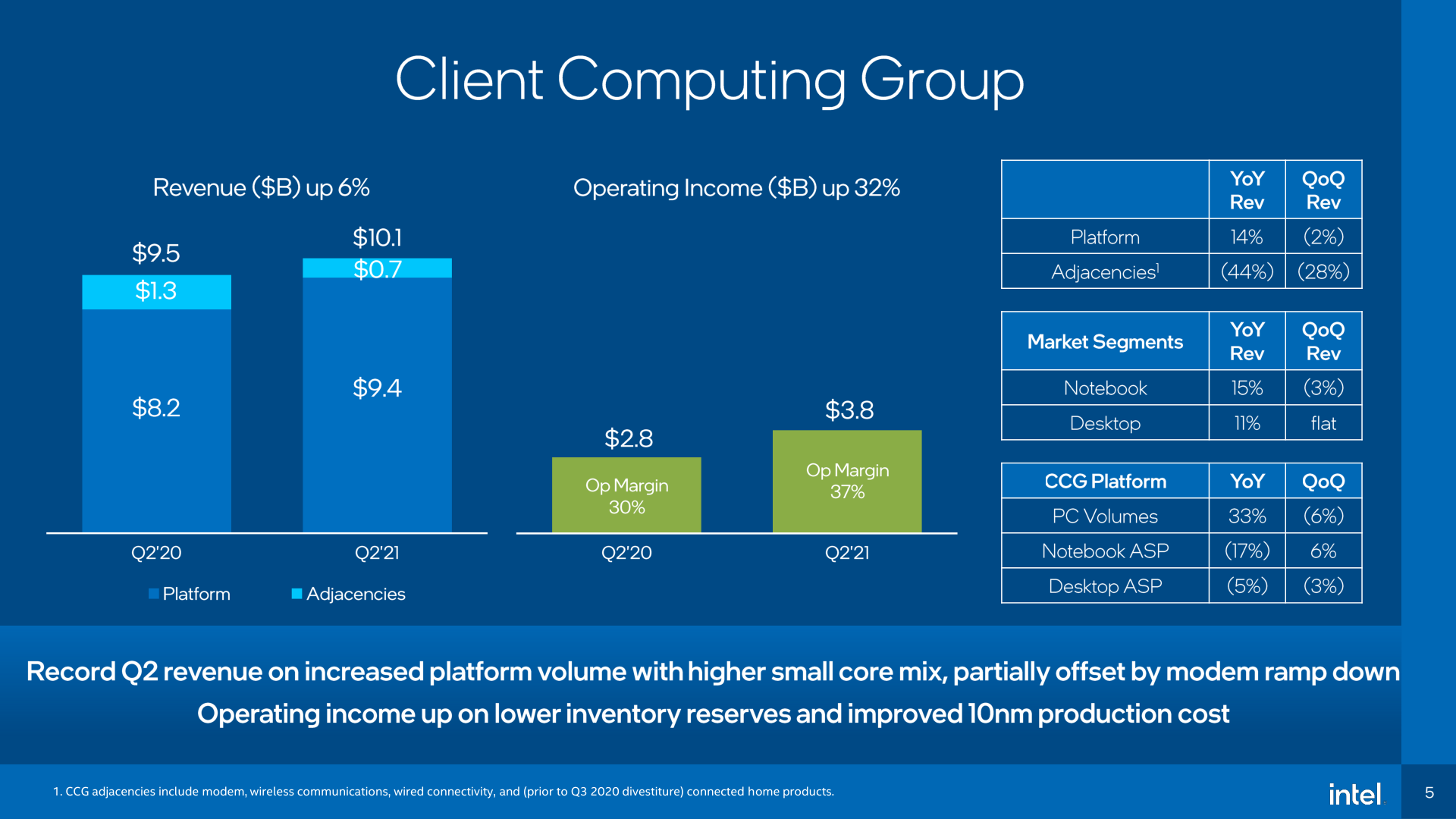

PC processor sales were up 33 percent year-over-year, which is why Intel’s Client Computing Group brought in a record $10.1 billion in revenue in the second quarter, 6 percent more than the same period last year. However, the average selling price of chips decreased as a result of a combination of factors, including high demand, chip shortages, and fierce competition from AMD in the gamer and enthusiast markets. After all, Intel reduced prices for 10th-gen Core processors to sway buyers away from AMD options, but still ended up selling more processors with lower core counts.

Gelsinger is optimistic about the semiconductor shortages and expects them to bottom out in the coming months. He also believes it will take up to two years before the industry is able to “completely catch up with demand.”

Intel’s Data Center Group saw revenue of $6.5 billion, which is down 9 percent YoY. The Non-volatile Memory Solutions Group brought in $1.1 billion, which is a 34 percent year-over-year decrease. Intel is currently in the process of selling off its NAND memory business to SK Hynix, but until that deal is finalized it still has the potential to stain Intel’s financial reports and business projections.

The IoT and Mobileye business units are up YoY. The former is up 47 percent, while the latter has surged 124 percent to bring in a record $327 million in revenue.

Elsewhere, Intel says “7nm is progressing well” and that it will start shipping large orders of Alder Lake chips to its partners in the coming months. The company has already shipped 50 million Tiger Lake processors to date, but doesn’t expect to be able to keep cranking them as easily in the third quarter due to an ongoing shortage of components and substrates.

Intel promised it will soon reveal more about its process and packaging roadmaps. Last year, the company had to admit it was falling behind schedule to develop a 7nm process node, but the company promised to fix fab issues and enlisted Pat Gelsinger to ensure it happens sooner rather than later.

Gelsinger established what he calls the “IDM 2.0” strategy, which is aimed to regain the crown of the “unquestioned” industry leader in process technology. So far, Intel has managed to increased its output of 10nm wafers to the point where it now exceeds 14nm wafers. As production of 10nm wafers ramps up, they’ll cost 45% less to make than they did a year ago, which is great news for the company’s bottom line.

In the coming years, Intel hopes to manufacture chips for other companies under a separate organization called Intel Foundry Services that will report directly to Gelsinger. The company is also building two 7nm fabs in Arizona and upgrading a third in New Mexico to manufacture advanced semiconductor packaging technologies, and we’ll no doubt hear more about them at the “Intel Accelerated” event next week on July 26.